Maintaining optimal temperature and humidity within your cold rooms is essential for preserving product quality and safety. A smart monitoring system provides real-time insights into your cold storage environment, allowing you to efficiently address any deviations from set parameters. This systems typically include sensors that monitor temperature, humidity, and other key metrics, transmitting data to a central platform for analysis and reporting. This clarity allows you to identify potential issues before they become major problems, minimizing product loss and ensuring regulatory compliance.

- Additionally, smart monitoring systems can automate alerts when predefined thresholds are breached. This provides immediate notification, allowing for swift action to resolve any temperature fluctuations or humidity changes.

- Ultimately, investing in a smart monitoring system for your cold rooms can lead to significant cost savings through reduced product spoilage, optimized energy consumption, and minimized downtime.

Cold Storage Maintenance

In the demanding world of food storage, reliable cold room equipment is paramount. We provide comprehensive services to ensure your cold rooms operate at peak efficiency. Our expert technicians are seasoned professionals and equipped to handle a wide range of tasks, from routine checks to complex system upgrades.

- Scheduled maintenance programs are crucial to minimize downtime and extend the lifespan of your cold room equipment.

- We offer prompt response times for emergency repairs, ensuring minimal disruption to your operations.

- Our commitment to customer satisfaction means we provide clear communication, transparent pricing, and reliable service every time.

Contact us today to learn more about our cold room services and how we can partner with you in maintaining a optimal environment for your valuable assets.

Deployment & Commissioning of Commercial Cold Room Systems

A meticulous deployment and commissioning process is paramount for ensuring the optimal performance and longevity of commercial cold room systems. This involves carefully locating the unit in accordance with manufacturer specifications, linking all electrical and refrigerant lines, and conducting a comprehensive testing to verify system functionality. A professional commissioning team will thoroughly analyze each component, fine-tuning settings as necessary to achieve the desired temperature control.

Upon successful completion of the commissioning process, a detailed report will be generated, documenting all system parameters and operational attributes. Routine maintenance and observation are essential for maintaining peak performance and extending the lifespan of your commercial cold room system.

Customized Cold Storage Solutions

Embarking on a cold room project requires meticulous planning and execution. Starting with an idea, our expert team collaborates closely with you to understand your specific requirements. We more info delve into the intricacies of your inventory type, quantity, and operational specifications. This comprehensive evaluation lays the groundwork for a tailored cold room design that precisely meets your unique demands.

Employing cutting-edge technology, we develop detailed plans that illustrate every component of your cold room system. Our team of skilled designers meticulously chooses the optimal components to ensure durability, performance, and compliance with industry standards.

- Installation commences with a focus on detailing to guarantee a robust and functional cold room structure. Our team of experienced craftsmen adheres to stringent compliance protocols throughout the workflow.

- Meticulous quality inspection measures are implemented at every stage to verify that your cold room meets the highest requirements.

Upon construction, we provide comprehensive training to your staff on the management of your new cold room. Our ongoing services are readily available to address any questions and ensure the successful performance of your investment.

Jasa Instalasi Mesin Cold Room: Reliable and Efficient Installation Service

When it's essential a reliable and efficient cold room installation, look no further than our expert team. We provide top-notch services for the deployment of all types of cold rooms, ensuring your inventory are stored at the perfect temperature. Our skilled technicians have a proven track record of delivering efficient installations with minimal disruption to your operations.

- We specialize in installing various types of cold rooms, including walk-in units, reach-in refrigerators, and blast freezers.

- We employ only the highest quality components and industry-approved practices to ensure a durable installation that meets your specific needs.

- Our commitment to customer satisfaction is unwavering. We provide thorough support throughout the entire installation process, from initial consultation to final testing and training.

Contact us today to schedule a consultation for your cold room installation project.

Unlocking Efficiency: IoT-Enabled Smart Monitoring for Cold Rooms

In the realm of product preservation, maintaining optimal temperature and environmental conditions is paramount. Enter the age of smart monitoring, where Internet of Things (IoT) sensors are revolutionizing cold room operations. These advanced platforms provide real-time data into critical parameters, enabling proactive optimization and minimizing loss. With IoT-enabled smart monitoring, operators can remotely monitor from anywhere, ensuring consistent consistency and reducing operational costs.

This proactive approach to cold room management brings a host of benefits, including reduced energy consumption, enhanced food safety, and improved accountability. By automating data collection and analysis, IoT-enabled smart monitoring frees up valuable time for operators to focus on other crucial tasks. Furthermore, the ability to detect anomalies in real-time allows for swift corrections, preventing costly disruptions and maintaining product integrity.

Mr. T Then & Now!

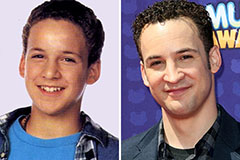

Mr. T Then & Now! Ben Savage Then & Now!

Ben Savage Then & Now! Michael Bower Then & Now!

Michael Bower Then & Now! Tatyana Ali Then & Now!

Tatyana Ali Then & Now! Ryan Phillippe Then & Now!

Ryan Phillippe Then & Now!